When you think of classic cars, you probably picture shiny chrome, sleek lines, and powerful engines. But there’s one component that often gets overlooked yet plays a crucial role in a car’s appearance and safety: the bumper. So, what were old car bumpers made out of? Let’s dive into the history and materials of vintage car bumpers.

The first bumpers appeared in the early 1900s, mainly as decorative accessories rather than functional safety features. Back then, they were simple metal strips attached to the front and rear of the car. These early designs were more about enhancing the car’s aesthetic rather than protecting it.

Cast Iron Bumpers

The very first car bumpers were made of cast iron. While cast iron is known for its durability, it was not the most effective material for absorbing impact. These bumpers were heavy and added significant weight to the vehicle, which could affect performance. Still, they set the stage for future developments in bumper technology.

Steel Bumpers

As automotive technology advanced, manufacturers started experimenting with different materials. By the 1920s, steel had become the standard material for car bumpers. Steel offered a better balance of strength, weight, and cost, making it an ideal choice for mass production. These steel bumpers were often painted to match the car’s body color, giving vehicles a more cohesive look.

The Rise of Chrome Bumpers

In the 1930s and 1940s, chrome plating became increasingly popular. Chrome bumpers were all the rage, giving cars a shiny, polished appearance that became synonymous with the classic car look. Chrome not only enhanced the aesthetic appeal but also provided a layer of protection against rust and corrosion.

The Process of Chrome Plating

Chrome plating involves electroplating a thin layer of chromium onto a metal surface. This process not only improves the bumper’s appearance but also increases its resistance to wear and tear. However, chrome plating is not without its drawbacks. It can be expensive and environmentally harmful due to the chemicals used in the process.

Post-War Innovations in Bumper Materials

After World War II, the automotive industry experienced a boom in innovation. Manufacturers began exploring new materials and designs to improve both the function and appearance of car bumpers.

Aluminum and Other Metals

In the 1950s and 1960s, aluminum started to be used in bumper construction. Aluminum is lighter than steel, which helped improve fuel efficiency and vehicle handling. However, aluminum is not as strong as steel, so it was often used in combination with other materials.

Plastic and Fiberglass Bumpers

By the late 1960s and early 1970s, plastic and fiberglass began making their way into bumper designs. These materials offered greater flexibility and could absorb impacts more effectively than their metal counterparts. However, they also had drawbacks, such as lower durability and susceptibility to UV damage.

The Evolution of Safety Standards

As cars became faster and more powerful, the need for better safety features became apparent. In the 1970s, governments around the world started implementing safety regulations that required bumpers to withstand specific impact tests. This led to the development of energy-absorbing bumpers that combined various materials for optimal performance.

Energy-Absorbing Bumpers

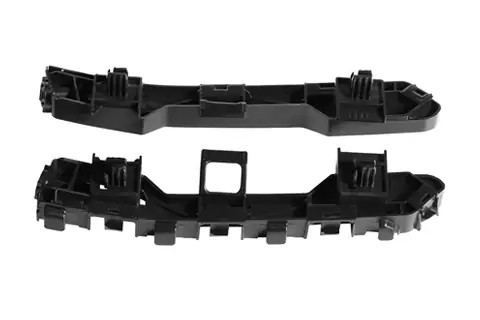

Energy-absorbing bumpers typically use a combination of metal and plastic components. A metal reinforcement bar provides structural support, while plastic covers and foam padding help absorb impact energy. These bumpers are designed to minimize damage to both vehicles involved in a collision and reduce the risk of injury to passengers.

Classic Car Bumpers Today

For car enthusiasts and collectors, maintaining the authenticity of classic cars is paramount. This means preserving or restoring the original bumpers using period-appropriate materials and techniques.

Restoring Vintage Bumpers

Restoring vintage car bumpers can be a labor of love. Depending on the condition of the bumper, this may involve removing rust, repairing dents, and re-chroming metal surfaces. In some cases, replacement parts may be necessary, and sourcing these can be challenging. However, the effort is worth it for those who appreciate the beauty and craftsmanship of classic cars.

Modern Reproductions

For those who want the classic look without the hassle of restoration, modern reproductions of vintage bumpers are available. These reproductions often use modern materials and manufacturing techniques to replicate the appearance of original bumpers while offering improved durability and performance.

Conclusion

The evolution of car bumpers reflects the broader trends in automotive design and technology. From cast iron and steel to chrome and plastic, each material has played a role in shaping the look and function of cars throughout history. Whether you’re a car enthusiast, collector, or simply curious about automotive history, understanding the materials and design of vintage car bumpers offers a fascinating glimpse into the past.

By preserving and appreciating these classic components, we can celebrate the ingenuity and craftsmanship of automotive pioneers and keep the spirit of vintage cars alive for future generations.