Before delving into the manufacturing process, it’s essential to understand the materials used in car bumper production. Car bumpers are typically made from a combination of plastic and metal. The choice of material depends on factors such as cost, weight, and the desired level of impact resistance. Selecting the right material is critical, as it influences the bumper’s performance, durability, and aesthetic appeal. The material selection process is a balance between engineering requirements and practical considerations, such as manufacturing costs and environmental impact.

Plastic bumpers are lightweight and offer excellent energy absorption properties. They are typically made from materials such as polypropylene, polycarbonate, or ABS (Acrylonitrile Butadiene Styrene). These plastics are chosen for their durability and flexibility, making them ideal for withstanding minor collisions. Moreover, plastic materials are easier to mold into complex shapes, allowing designers to create bumpers that enhance the vehicle’s overall look. The use of plastics also contributes to improved fuel efficiency due to the reduced weight of the vehicle. Environmental considerations are increasingly influencing the choice of plastics, with manufacturers exploring bio-based or recycled materials to reduce their carbon footprint.

Metal bumpers, on the other hand, provide superior strength and durability. They are often made from steel or aluminum, which can withstand more significant impacts. However, metal bumpers are heavier than their plastic counterparts, which can affect vehicle performance and fuel efficiency. Despite their weight, metal bumpers are favored in certain vehicles, such as trucks and SUVs, where durability and heavy-duty performance are prioritized. The choice between steel and aluminum involves trade-offs; steel offers higher strength, while aluminum provides a lighter alternative with good corrosion resistance. Additionally, innovations in material science are leading to the development of high-strength, lightweight alloys that offer the benefits of both materials.

Once the materials are selected, the manufacturing process begins with molding. This step is crucial in shaping the bumper to fit the specific design of a vehicle. Molding not only dictates the structural integrity of the bumper but also influences its aesthetic qualities. Let’s take a closer look at the molding process for both plastic and metal bumpers, which involves sophisticated machinery and precise engineering to achieve the desired outcomes.

The production of plastic bumpers typically involves injection molding. This process begins with melting plastic pellets and injecting them into a mold cavity under high pressure. The mold is designed to match the exact shape and dimensions of the bumper. Once the plastic cools and solidifies, the mold is opened, and the bumper is ejected. Injection molding allows for precise control over the shape and thickness of the bumper, ensuring a perfect fit for each vehicle model. Additionally, it enables the production of complex designs and intricate details that enhance the bumper’s aesthetic appeal. The efficiency of injection molding makes it ideal for mass production, as it allows for high-speed manufacturing with consistent quality. Moreover, advancements in mold-making technology have enabled the creation of more detailed and complex designs, further pushing the boundaries of automotive aesthetics.

Metal Bumper Molding

Metal bumpers are produced through a process known as stamping. Large metal sheets are fed into a stamping press, where they are cut and shaped into the desired bumper form. The press applies immense force to bend and shape the metal, creating a robust and durable bumper. Stamping is a highly efficient process, allowing for the rapid production of metal bumpers. However, it requires precision to ensure that each bumper meets the required specifications and fits perfectly on the vehicle. The stamping process can also include additional operations such as piercing, trimming, and hemming to refine the bumper’s shape and functionality. Automation in stamping has increased productivity and reduced production costs, making it a preferred choice for large-scale manufacturing. Moreover, computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have enhanced the precision and efficiency of the stamping process, ensuring that metal bumpers meet stringent quality standards.

Surface Finishing

After molding, the bumpers undergo surface finishing to enhance their appearance and protect them from environmental factors. This step is crucial in ensuring the durability and longevity of the bumper. Surface finishing not only improves the visual appeal of the bumpers but also provides a protective barrier against corrosion, UV radiation, and other environmental challenges. The finishing process varies depending on whether the bumper is made of plastic or metal, with each requiring specific techniques to achieve the desired results.

Plastic Bumper Finishing

Plastic bumpers are typically sanded and polished to remove any imperfections and achieve a smooth surface. They are then coated with a layer of primer, followed by a base coat of paint. The final step involves applying a clear coat, which provides a glossy finish and protects the paint from scratches and UV rays. The application of these coatings is often automated, ensuring uniform coverage and quality. Additionally, manufacturers are exploring eco-friendly paints and coatings to minimize environmental impact while maintaining high standards of durability and aesthetics. The finishing process can also include the integration of textures or patterns, adding an extra dimension to the bumper’s design.

Metal Bumper Finishing

Metal bumpers undergo a similar finishing process, starting with sanding and polishing to eliminate any rough edges or blemishes. They are then treated with a corrosion-resistant coating to prevent rust and enhance their durability. Like plastic bumpers, metal bumpers are also painted and finished with a clear coat for added protection and aesthetic appeal. The choice of paint and coatings for metal bumpers is critical, as it must withstand the rigors of outdoor conditions while maintaining a visually appealing finish. Advanced surface treatments, such as powder coating, offer increased durability and resistance to chipping, making them a popular choice for metal bumpers. Furthermore, innovative technologies such as electrophoretic deposition (e-coating) are being used to apply coatings more evenly and efficiently.

Assembly and Quality Control

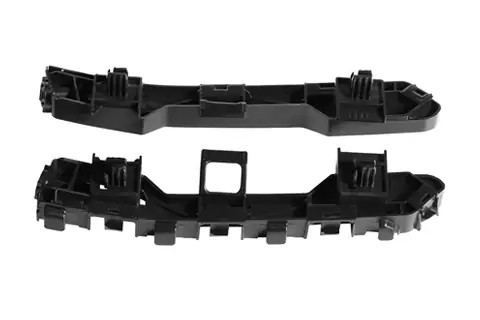

Once the bumpers are finished, they are ready for assembly. This step involves attaching any additional components, such as mounting brackets, sensors, or fog lights. The assembled bumpers are then subjected to rigorous quality control tests to ensure they meet safety and performance standards. Assembly is a critical phase where precision and attention to detail are paramount, as even minor discrepancies can affect the bumper’s functionality and safety. Automation plays a significant role in the assembly process, enhancing efficiency and accuracy.

Quality Control Tests

Quality control is a critical aspect of the manufacturing process, as it ensures that each bumper meets the required safety and performance criteria. Tests may include impact resistance, fitment accuracy, and paint adhesion. Any defects or discrepancies are identified and rectified before the bumpers are approved for installation on vehicles. Quality control involves both automated and manual inspection techniques, providing a comprehensive evaluation of each bumper’s quality. Advanced testing equipment simulates real-world conditions to ensure that bumpers can withstand various impacts and environmental challenges. Continuous improvement processes and feedback loops are integral to quality control, allowing manufacturers to identify areas for enhancement and innovation.

Conclusion

The manufacturing process of car bumpers is a complex and fascinating journey, involving material selection, molding, finishing, and assembly. Each step is carefully executed to ensure that the bumpers provide optimal safety, performance, and aesthetics. Understanding how car bumpers are made can give you a greater appreciation for these essential vehicle components. Whether plastic or metal, bumpers play a vital role in protecting both the vehicle and its occupants, making them an indispensable part of automotive design and engineering.

By exploring the intricacies of bumper production, we gain insight into the dedication and precision required to create these essential vehicle components. As technology continues to advance, the future of car bumper manufacturing promises even greater innovations in safety and design. Emerging technologies, such as 3D printing and smart materials, are set to revolutionize the industry, offering new possibilities for customization and performance. As manufacturers strive to meet evolving consumer demands and regulatory standards, the bumper manufacturing process will continue to be at the forefront of innovation and excellence in automotive engineering.